Automated Wet Chemical Processing Systems

COMMON FEATURES

| SAFETY FEATURES

|

FLEXIBILITY

| SIMPLICITY/RELIABILITY/ SERVICEABILITY

|

|  |

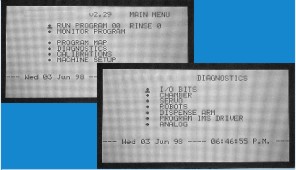

Model 3145 | Easy-to-read, menu-driven software |

MODEL 3110 CLEANERApplications:– Organic Clean

– Particulate Clean

– Final Clean

– Spin Dry – Automatic Chamber Rinse before next substrate processed | MODEL 3140 DEVELOP, ETCH or STRIP SYSTEMApplications:– Spray Develop for Laser Exposed Positive Resist – Spray Etch of chrome – Resist Strip

– Automatic Chamber Rinse before next substrate processed | MODEL 3140 DEVELOP and ETCH SYSTEMDevelop/Etch Process:

– Automatic Chamber Rinse before next substrate processed |