COMMON FEATURES- Simplicity = Reliability

- Small System Footprint (30.5″W x 43″D x 60.5″H) (775 mm x1092 mm x 1537 mm)

- Effective Chemical Drain Diversion

- Large (24″, 609 mm) Diameter Process Chamber

- Up to 6 nozzles for Chemistry + Top Side Rinse

- Up to 8 nozzles for Thorough Chamber Rinse

- Uniform Process Airflow

- Recessed Spray Nozzles, optional Drain Diversion

| SAFETY FEATURES- Notification When Beneficial; Hard Shutdown Only When Necessary

- Extensive Safety Interlocking Through both Hardware and Software

- Double Containment for Chemistry

- Total Isolation of Chemicals and Electronics

- Transparent, Interlocked Chamber Door

- Anti-Splashback Design

Protection for Operators

|

FLEXIBILITY- Systems Dedicated to a Single Process, or Combination Systems Performing Multiple Processes

- A Wide Variety of Options to Customize the System for Your Application(s)

– Binary, Fan, Stream and/or High Pressure Jet Nozzles

– Variety of Canisters, Pumps, Exhausts, Drains, Brushes, etc; with or without Chemical Temperature Control

| SIMPLICITY/RELIABILITY/ SERVICEABILITY- Elegantly Simple Design

- Standard Parts Used Throughout

- Field-Proven Reliability

- Easy Access to All Areas forMaintenance/Service

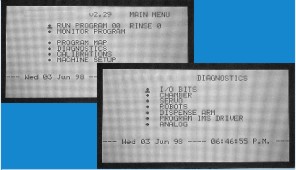

- Password Protected Screens

- Protection Against Operator Error

|